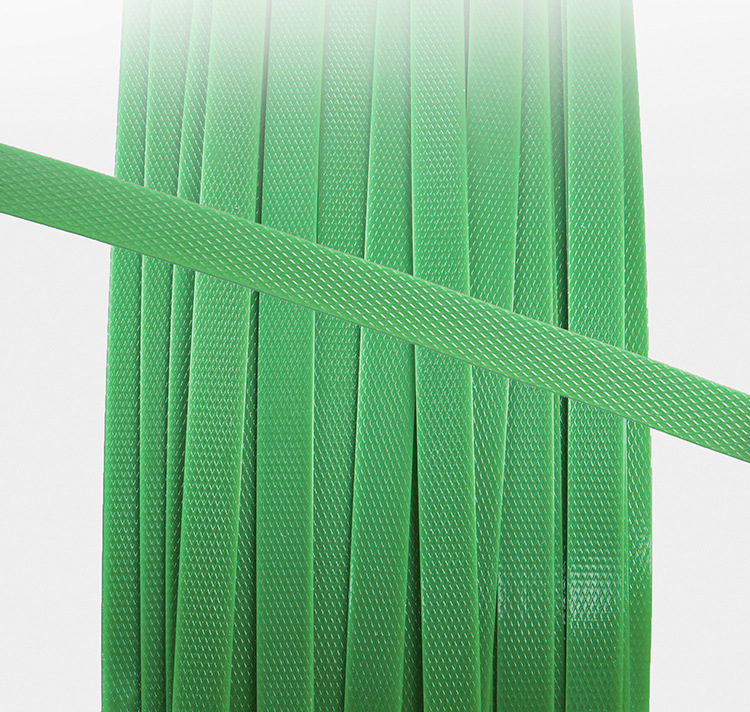

Pallet Packaging Polyester PET Strapping Banding Roll

Polyethylene Terephthalate (PET) strapping has become a cornerstone in modern packaging, offering a reliable and efficient solution for securing goods across various industries. Its unique combination of strength, durability, and environmental benefits positions it as a superior alternative to traditional strapping materials like steel and polypropylene (PP).

Understanding PET Strapping

PET strapping is a type of plastic strapping made from polyester fibers. Renowned for its high tensile strength and flexibility, it effectively absorbs the force of heavy loads without breaking, making it ideal for heavy-duty applications. Unlike steel straps, PET straps do not rust, reducing the risk of product contamination during storage or transportation.

Advantages of PET Strapping

- High Tensile Strength: PET straps can maintain tension over time, ensuring that heavy loads remain securely fastened during transit and storage.

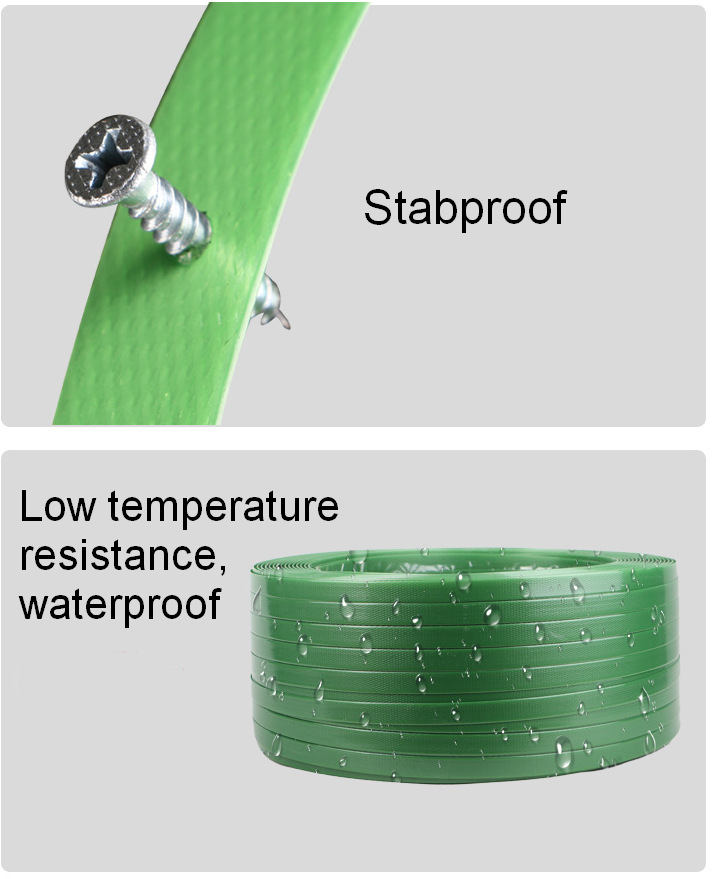

- Weather Resistance: PET strapping is resistant to high temperatures, UV rays, and humidity, retaining its shape and strength even under extreme weather conditions.

- Cost-Effectiveness: Compared to steel strapping, PET straps are more economical and do not require additional protective materials to prevent damage to goods, leading to substantial cost savings.

- Safety: The flexibility and smooth edges of PET straps minimize the risk of injuries during handling, unlike steel straps that have sharp edges and can recoil dangerously when cut.

- Environmental Sustainability: Manufactured from recycled materials, PET straps are recyclable, aligning with eco-friendly practices and reducing the environmental footprint.

Applications of PET Strapping

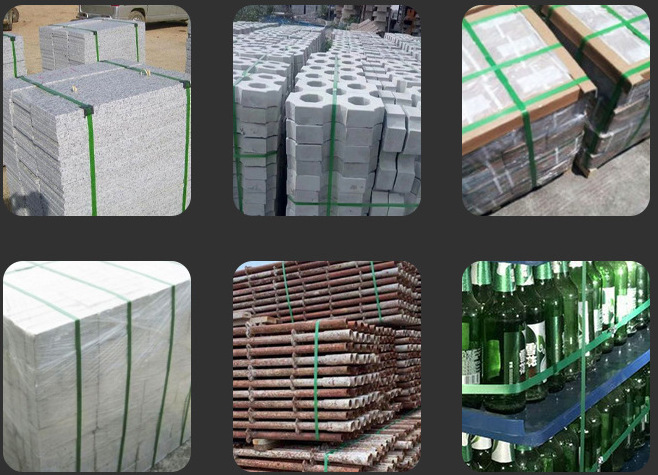

The versatility of PET strapping makes it suitable for a wide range of applications:

- Construction Industry: Used to secure heavy materials like bricks, timber, pipes, and tiles, ensuring they remain intact during transport and storage.

- Automotive Sector: Ideal for securing components such as engines, tires, and glass, thanks to its shock-absorbing capabilities that protect against damage during shipments.

- Electronics Industry: Provides protection for high-value electronic devices during transportation, safeguarding them from compression and impact.

- Logistics and Warehousing: Ensures the safe arrival of products by keeping goods securely in place during transit, thereby enhancing overall transport efficiency.

PET Strapping vs. PP Strapping

While both PET and PP strapping are used in packaging, they have distinct differences:

- Strength and Durability: PET strapping offers higher tensile strength and better tension retention, making it suitable for heavy-duty loads.

Environmental Resistance: PET straps exhibit excellent resistance to UV rays, heat, and moisture, whereas PP straps are less resistant to environmental factors.

- Cost Considerations: PP strapping is generally more cost-effective for lightweight applications, while PET strapping, though slightly more expensive, provides better value for demanding applications due to its superior performance.

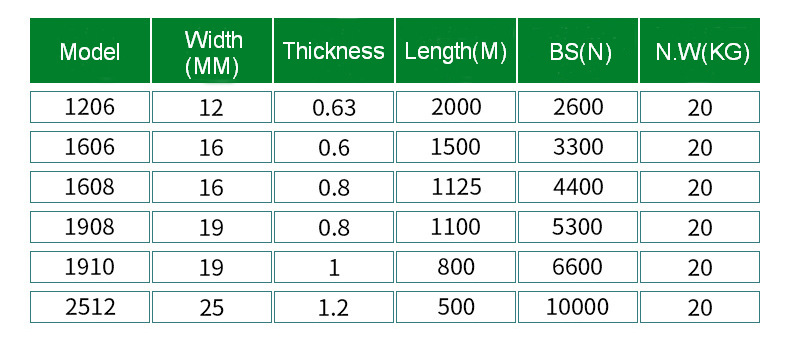

Model Number: WDPET-1608

-

Cautions:

Choose the suitable size of strap.

Never overload

Do not twist the strap.