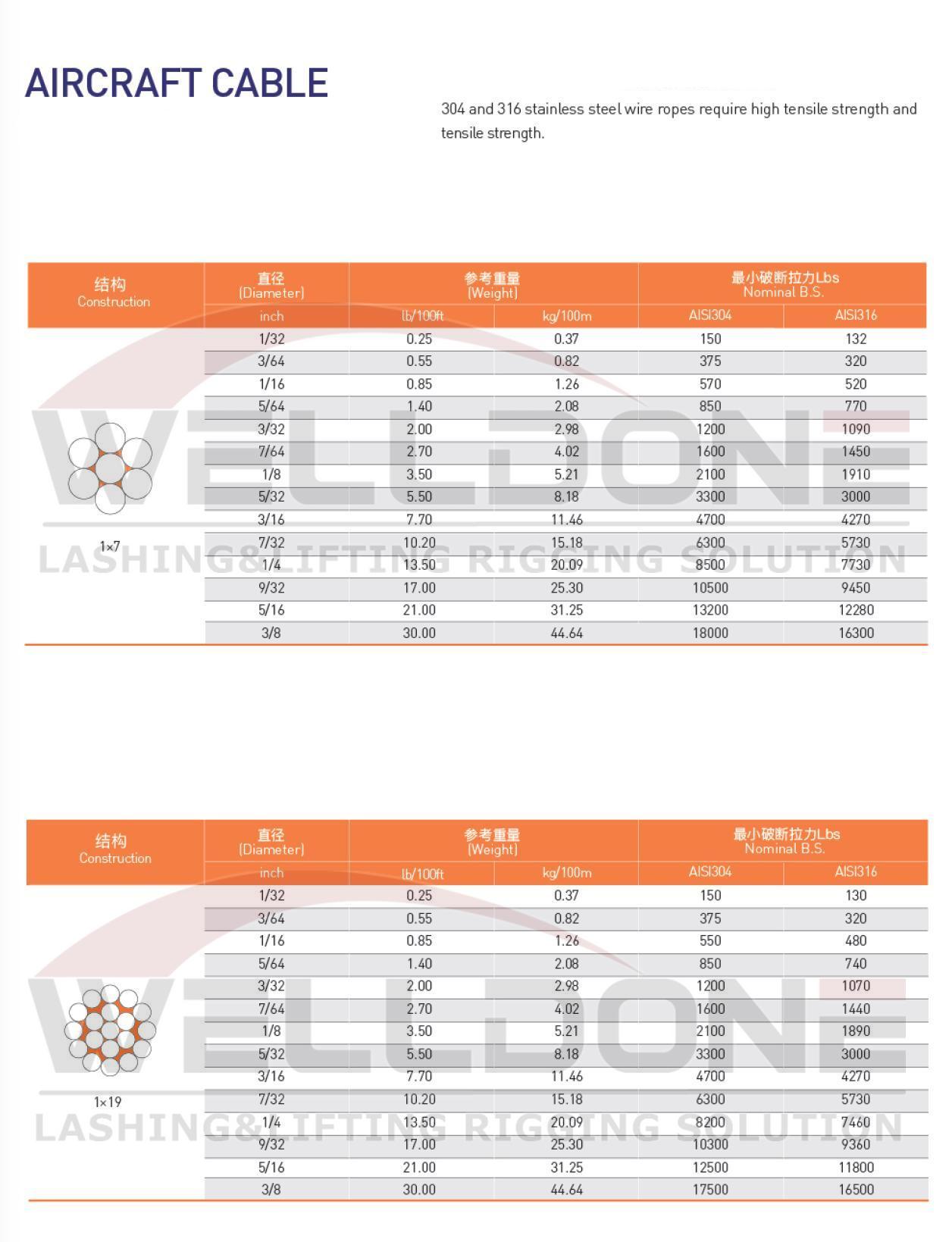

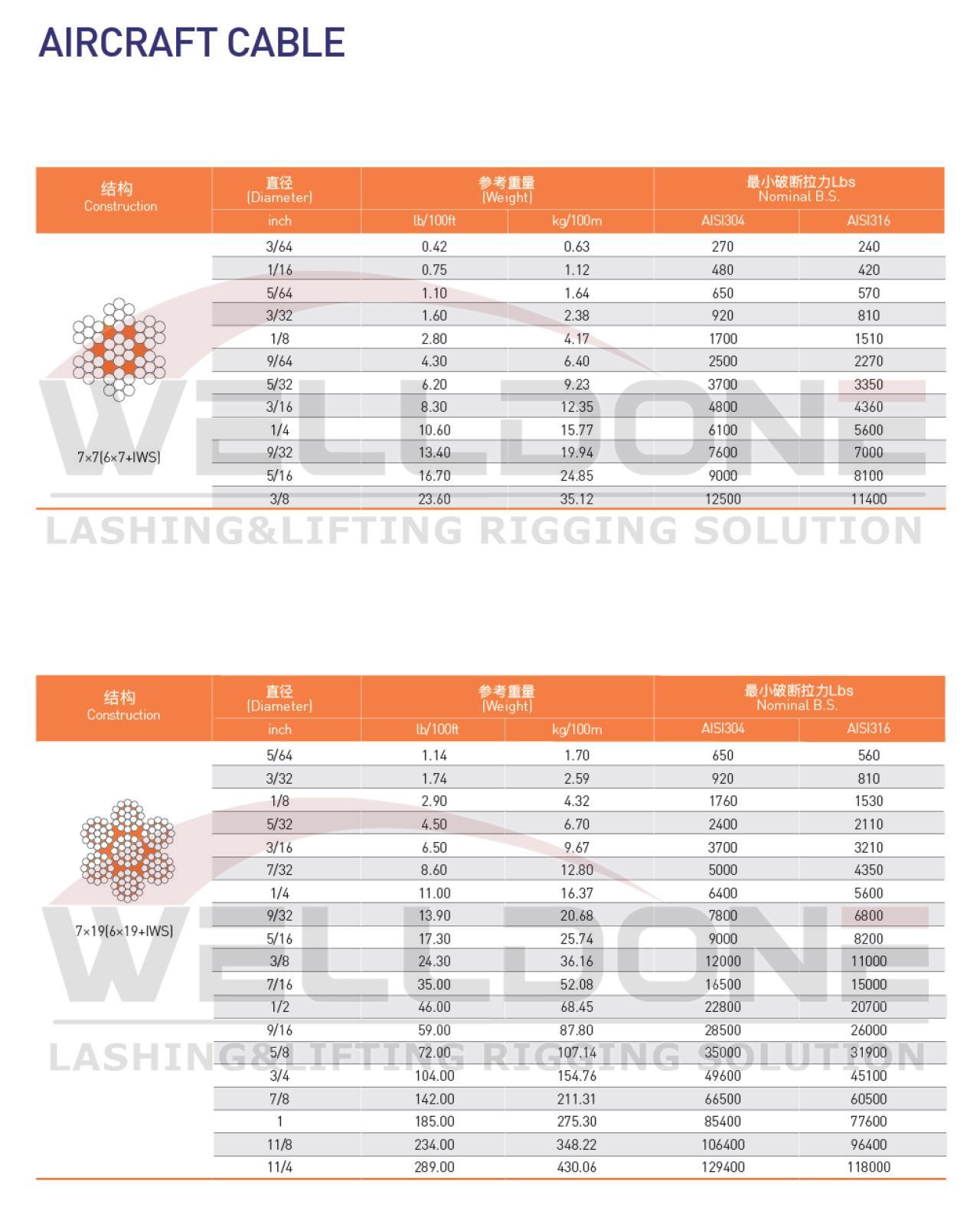

304 / 316 Stainless Steel Wire Rope 1*7/1*19/7*7/7*19 Aircraft Cable

Stainless steel wire rope is a versatile and robust material widely used in various industries due to its excellent strength, durability, and resistance to corrosion. Its unique properties make it an essential component in many applications, from construction and marine environments to aviation and industrial machinery.

Composition and Types

Stainless steel wire rope is typically composed of a combination of steel and chromium, with other elements such as nickel, molybdenum, and carbon added to enhance specific properties. The inclusion of chromium gives stainless steel its renowned corrosion resistance, while other elements improve its strength and durability.

There are several types of stainless steel wire rope, each designed for specific applications:

- 1×19 Wire Rope: Comprising a single strand of 19 wires, this type is known for its high tensile strength and minimal stretch. It is often used in applications requiring low flexibility, such as guy wires and structural support.

- 7×7 Wire Rope: Made up of seven strands, each containing seven wires, this type balances flexibility and strength. It is commonly used in rigging, slings, and control cables.

- 7×19 Wire Rope: This type consists of seven strands with 19 wires each, providing greater flexibility than the 7×7 configuration. It is ideal for applications that require more movement and flexibility, such as winches, pulleys, and lifting gear.

Key Properties

- Corrosion Resistance: One of the most significant advantages of stainless steel wire rope is its resistance to corrosion. This makes it suitable for use in harsh environments, including marine and chemical industries, where exposure to moisture and corrosive substances is common.

- Strength and Durability: Stainless steel wire rope is known for its exceptional strength and durability. It can withstand high levels of tension and pressure, making it ideal for heavy-duty applications such as lifting, towing, and structural support.

- Flexibility: Depending on the strand configuration, stainless steel wire rope can offer varying degrees of flexibility. This property is crucial for applications that require bending and movement, such as in cranes and elevators.

- Temperature Resistance: Stainless steel wire rope can maintain its properties over a wide range of temperatures, making it suitable for use in both high-temperature industrial processes and freezing conditions.

Applications

The versatility of stainless steel wire rope allows it to be used in a myriad of applications across different industries:

- Construction: In the construction industry, stainless steel wire rope is used for structural support, safety barriers, and lifting operations. Its strength and durability make it ideal for use in skyscrapers, bridges, and other large structures.

- Marine: The corrosion resistance of stainless steel wire rope makes it indispensable in the marine industry. It is used in mooring lines, rigging, and fishing equipment, where exposure to saltwater and harsh weather conditions is a concern.

- Aviation: In the aviation sector, stainless steel wire rope is used in control cables, securing aircraft components, and cargo handling. Its strength and reliability are critical for ensuring the safety and performance of aircraft.

- Industrial Machinery: Stainless steel wire rope is also used in various industrial machines and equipment, including cranes, elevators, and conveyors. Its ability to withstand high tension and harsh operating conditions makes it a preferred choice for these applications.

Model Number: 1*7/1*19/7*7/7*19

Take measures to protect the wire rope from corrosion, especially in corrosive environments such as marine or industrial settings. This may include regular cleaning, coating with rust inhibitors, or using stainless steel ropes in corrosive environments.

Never exceed the rated capacity of the wire rope.

Wire Rod—Pickling&Surface treatment—Drawing—Patenting—Plating—Stranding&Closing